Since its establishment over 20 years ago, our company has achieved substantial milestones in aluminum processing equipment manufacturing. As of November 2021, we have successfully delivered 98 aluminum foil rolling mills, 32 aluminum cold rolling mills, 140 aluminum foil slitting and rewinding lines, 70 aluminum strip finishing lines, and 33 aluminum hot rolling and continuous casting lines. This strong foundation has enabled us to support major industrial projects across the globe. Below are some of the key customer cases that showcase our expertise and commitment to quality.

2022 Shenhuo GroupIn 2022, Shenhuo Group invested in a new energy battery aluminum foil production line with an annual capacity of 60,000 tons. They selected a full set of next-generation aluminum foil rolling mills designed and manufactured by our company, including 8 aluminum foil rolling mills, 1 aluminum foil rewinding machine, and 8 aluminum foil slitting machines. The project was completed in 24 months and is now fully operational, supplying high-quality battery aluminum foil to major companies like CATL (Contemporary Amperex Technology Co., Limited) and BYD.

2022 Guizhou Chalco AluminiumIn 2022, Guizhou Chalco Aluminium invested in a production line for aluminum foil used in new energy power batteries, with an annual capacity of 30,000 tons. To support this project, they selected 6 aluminum foil slitting machines designed and manufactured by our company. These high-performance machines ensure precise slitting and efficient processing, contributing to the growing demand for aluminum foil in the energy storage sector.

2022 China Energy Engineering CorporationIn 2022, China Energy Engineering Corporation launched a production line with an annual capacity of 30,000 tons for new energy battery aluminum foil. To support this large-scale project, the company selected a complete set of advanced aluminum foil processing equipment designed and manufactured by us, including 6 aluminum foil rolling mills, 1 aluminum foil rewinding machine, and 6 aluminum foil slitting machines. The construction was completed in 28 months, and the facility is now fully operational, supplying high-quality aluminum foil materials for China Energy Engineering Corporation's internal energy storage projects, reinforcing their commitment to sustainable energy development.

Inner Mongolia LianshengThe hazelett three-stand hot rolling mill installed at inner mongolia liansheng is the second of its kind in China and the first fully manufactured domestically. This advanced three-stand configuration enhances production efficiency and ensures high-quality rolling performance, marking a significant step forward for Chinese manufacturing in hot rolling technology.

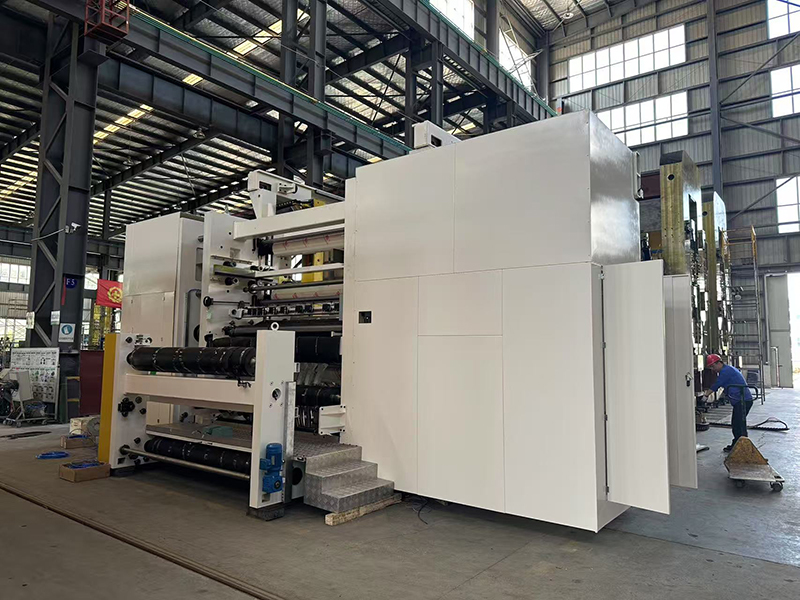

China's First 2200mm Wide Aluminum Cold Precision Rolling MillWe successfully designed and manufactured China's first 2200mm wide two-stand aluminum cold precision rolling mill. This advanced equipment is engineered to deliver high-precision rolling for wide-width aluminum sheets, enhancing production efficiency and product quality in the aluminum processing industry.

China's Second 2300mm Wide Two-Stand Cold Rolling MillWe designed and manufactured China's second 2300mm wide two-stand cold rolling mill. This high-performance equipment is built for exceptional speed and efficiency, with the second mill stand achieving a maximum speed of 1500 m/min, significantly boosting productivity and processing capacity.

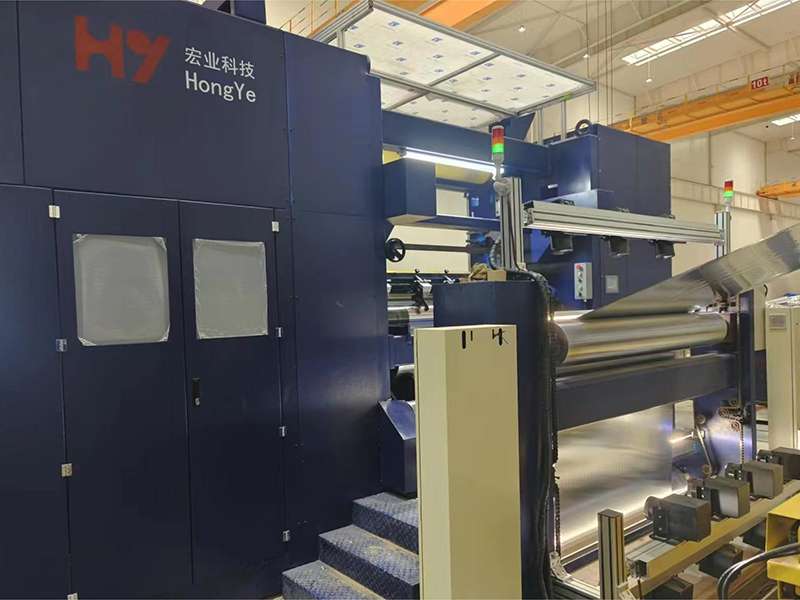

China's Widest 2300mm Aluminum Foil Slitting MachineOur company successfully designed and manufactured China's widest 2300mm aluminum foil slitting machine, equipped with an automatic unloading system. This advanced setup streamlines production by enabling efficient slitting and smooth unloading, enhancing productivity and ensuring high-quality processing of wide-width aluminum foil.